The Role of Drum Palletizers in Modern Manufacturing

In today’s fast-paced industrial world, where efficiency and safety are key, drum palletizers are changing the way materials are handled. These machines use automation to improve how drums are stacked on pallets, making the process faster and safer.

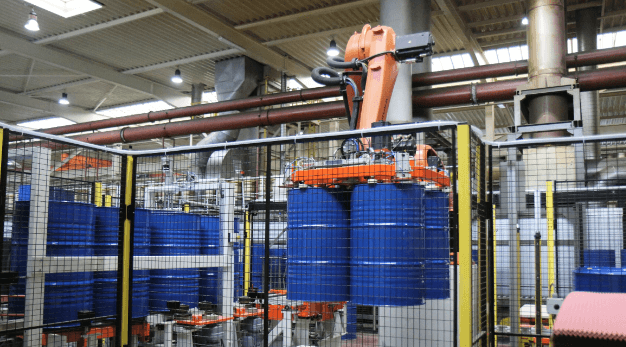

Understanding Drum Palletizers

Drum palletizers are machines designed to stack drums onto pallets. They reduce the need for manual labor, making the process smoother and less physically demanding for workers.

Automatic vs. Semi-Automatic Drum Palletizers

There are two main types of drum palletizers: automatic and semi-automatic. Automatic drum palletizers handle the entire process without human help, while semi-automatic ones need some human input. Each type has its own benefits, balancing between full automation and some human control.

Key Features of Drum Palletizers

Choosing the right drum palletizer involves looking at several important features. These include the load capacity, safety measures, and how well the machine can fit into the existing production line. Good drum palletizers have features that make them efficient and easy to integrate into different industrial settings.

Benefits of Using Drum Palletizers

Using drum palletizers offers many benefits. They improve efficiency, reduce labor costs, and increase safety. By automating the stacking process, these machines make material handling more precise and reliable.

Applications of Drum Palletizers in Different Industries

Drum palletizers are used in many industries, from petrochemicals to pharmaceuticals. They help ensure that drums are handled carefully and in compliance with industry standards, making them essential for maintaining efficiency and safety.

Factors to Consider When Choosing Drum Palletizers

Selecting the right drum palletizer means considering several factors. These include the available space, the need for customization, and how the machine will fit into the current production process. Each of these factors helps ensure that the drum palletizer will work well in the intended setting.

Customization of Drum Palletizers

Customization is key to making drum palletizers work well for specific needs. By tailoring these machines to handle different types of drums and stacking patterns, they can be made to fit perfectly into any industrial operation.

The Importance of Drum Palletizers in Industrial Progress

Drum palletizers are important for the progress of modern industry. They represent a blend of innovation and practical use, creating new ways to improve efficiency and safety in material handling.

The Lasting Impact of Drum Palletizers

As industries continue to evolve, drum palletizers will remain important in the world of industrial automation. They represent the spirit of innovation and the drive for excellence, ensuring that each drum is stacked safely and efficiently.

Drum palletizers are changing how industries handle materials. By automating the stacking process, they improve efficiency, reduce labor costs, and increase safety. These machines are essential in various industries, from petrochemicals to pharmaceuticals, making them a key part of modern manufacturing.